How to bake the Chemical Cake

Brought to you by Irrational Beef INC & Senate

Mix 5 ml of phenylacetone and 10 ml of N-methylformamide in a clean dry test tube or similar small glass container. Within a few seconds they should mix together entirely.

- If they do not mix, there is water in the N-methylformamide, and it must be distilled under vacuum rigorously.

Mix 100 ml phenylacetone with

Place 250 ml N-methylformamide in a 500 ml round bottom flask. Add one per cent by weight of Raney nickel to the N-methylformamide. Ensure the flask is sitting in an oil bath, to supply even heating to the flask.

- The oil (Wesson is a good choice) should extend about 2/3 of the way up the side of the flask.

A low heat setting is used so that the rise in temperature can be closely controlled, and a thermometer is placed inside the flask.

The rise in temperature of both the oil bath and the flask is monitored. Every degree of temperature increase from here on must be carefully controlled.

The contents of the flask are stirred regularly with the thermometer. Once 90 C has been reached, slowly drip in 100 ml phenylacetone over the course of an hour, allowing the temperature to reach 120 C.

Once reached, turn heat down to stabilize.

- At 105°C, the reaction kicks in, although sometimes the heat must go as high as 110°C before it starts.

Add a small amount of aluminum sulfate or aluminum foil to catalyze reaction.

When the reaction starts, the contents of the flask begin to bubble. To get this reaction going at a nice low temperature, gently scrape the thermometer along the bottom of the flask.

Keep the temperature down at the same level at which the reaction first began for as long as the reaction will continue at that level. Generally, a couple of hours before an increase in temperature is necessary.

- The reaction mixture has the same color as beer and gently bubbles CO2.

When the rate of bubbling slows down to almost stopping, it is time to raise the temperature. It should only be raised about 3°C. For the duration of the reaction, the contents of the flask are stirred with the thermometer every 30 min.

- The highest yield of the product is obtained when the lowest possible temperature is used.

As the reaction decreases, repeat the temperature increase of a few degrees.

It will be able to stay in the 120°C to 130°C range for a long time. After 24 to 36 hours, 140°C to 145°C is reached and the reaction stops.

- Take time working up to this temperature because the amount and quality of the product depends on it.

Turn off heat and allow the contents to cool. It should still look like beer. A reddish tint is unacceptable and must be restarted.

While cooling, react the unused N-methylformamide with a strong solution of sodium hydroxide. The N-methylformamide is hydrolyzed to form methylamine gas and sodium formate.

The methylamine gas produced is piped into formic acid to make N-methylformamide for use in the next batch.

180 grams of sodium hydroxide pellets are added to 450 ml of water, and once cooled, it is poured in a 2000 ml round bottom flask with 5 boiling chips. Then all of the reaction mixture is poured into the flask and the flask will sit on the heat source. The bent piece of glass tubing leads to a 1000 ml round bottom flask equipped with a condenser. The 1000 ml flask contains 250 ml of 88% formic acid.

The heat source is turned on to about 113°C maximum.

Begin the flow of ice water through the long condenser. Eventually, the boiling chips float up to the interface of the sodium hydroxide solution and the reaction mixture, and some bubbling and frothing of the reaction mixture begins.

Heat is turned down and the temperature of the mixture should rise slowly from now on.

- Methylamine hydrolysis tends to kick in all at once if this precaution is not taken.

After the first rush of the reaction has subsided and the bubbling of the methylamine into the formic acid has slowed down, increase heat applied to the 2000 ml flask to maintain a good rate of methylamine flow to the formic acid.

Eventually, all the methylamine will be boiled out. The flask must not be heated so strongly that water is forced through the bent glass tubing.

Heat is turned off and the level of the formic acid flask is lowered so that the acid is not sucked back into the other flask.

- The formic acid is about half reacted with methylamine. When it has cooled down, it is poured in a tall glass bottle and kept in the freezer until the next batch is made, when it is used for the production of N-methylformamide.

- Since it is already half reacted, the amount of methylamine used is reduced accordingly.

Meanwhile, back in the 2000 ml flask, the reaction mixture is about 100 ml in volume and has a red color, and floats above the sodium hydroxide solution. Once it has cooled down, the contents of this flask are poured into a 1000 ml separatory funnel. The sodium hydroxide solution is drained out and thrown away. The red m-formyl amide is poured into a 500 ml round bottom flask with 3 boiling chips.

200 ml of 28% hydrochloric acid is measured out.

11 ml is poured into the sep funnel and swirled around to dissolve any product left behind in the sep funnel. Then it is poured into the 500 ml flask with the product. When swirling around, they mix easily.

Tap water flow is proper for use in the condenser. The heat is turned on to the 500 ml flask, and a gentle rate of boiling is maintained for 2 hours.

- The mixture quickly turns black.

After the two hours have passed, the heat to the flask is turned off.

While the flask is cooling down, 80 grams of sodium hydroxide and 250 ml of water are mixed in a 1000 ml round bottom flask. If the 35% hydrochloric acid was used in the last step instead of 28%, then 100 grams of sodium hydroxide is mixed with 300 ml of water.

When both flasks have cooled down, the black reaction mixture is cautiously added in small proportions to the sodium hydroxide solution. When the sodium hydroxide solution gets very hot, stop adding the reaction mixture to it until it cools down again. After all the black reaction mixture has been added to the sodium hydroxide solution, there is a brown liquid layer floating above the sodium hydroxide solution.

The 1000 ml flask is stoppered and shaken vigorously for 5 minutes.

100 ml of water to the flask and swirled for a few minutes to dissolve salts. If that does not dissolve it all, add another 100 ml of water.

After the flask has cooled down, it is poured into a 1000 ml sep tunnel, and 100 ml of toluene is added.

The sep funnel is stoppered and shaken for 15 seconds.

It is allowed to stand for a couple of minutes, then the lower water layer is drained into a glass container.

The brown layer is poured into a clean, dry 50 ml round bottom flask. The water layer is extracted once more with 100 ml toluene, then thrown away. The toluene layer is poured into the 500 ml flask along with the rest of the solution.

Add three boiling chips to the 500 ml round bottom flask and set up glassware for fractional distillation.

The 500 ml flask sits directly on the heat source. The glass-packed claisen adapter is the proper fractionating column. The collecting flask is a 250 ml round bottom flask. Tap water is used in the condenser.

The heat source is turned on to 1/4 1/3 maximum. Soon the mixture begins boiling. The first thing that distills is toluene-water azeotrope at 85° C. Then pure toluene comes over at 110°C.

When the temperature reaches 115°C. or the rate of toluene collecting slows to a crawl, the heat is turned off and the flask allowed to cool down.

- The collected toluene is poured into a bottle. It can be used again the next time this process is done.

The same 250 ml flask is put on the collecting side.

The distilling flask is now cool, so vacuum is applied to the glassware at lull strength. The last remnants of toluene begin to boil, and the heat is turned back on to 1/3 maximum. The temperature begins to climb. If an aspirator is being used, when the temperature reaches 80° C, quickly remove the vacuum hose and replace the 250 ml flask with a clean dry one. If using a good vacuum pump, make this change at about 70° C.

- The flask change is done quickly to avoid overheating in the distilling flask.

The product distills over.

With an aspirator, collect from 80°C to about 140°C or 150°C, depending on how strong the vacuum is. With a vacuum pump, collect to about 120°C or 130°C. Once it has distilled, the heat is turned off and the vacuum hose disconnected.

- The product is about 90 ml of clear to pale yellow product.

Half of the product is put into each of two clean, dry 500 ml Erlenmeyer flasks.

With ether, rinse the insides of the condenser, vacuum adapter and 250 ml flask to get out the product clinging to the glass. This rinse is poured in with the product. Solvent is added to each of the Erlenmeyer flasks until the volume of liquid is 300 ml. They are mixed by swirling.

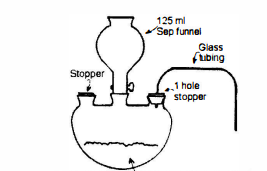

The glassware is set up as shown:

Bend another piece of glass tubing to the shape shown. It should start out about 18 inches long. One end should be pushed through a one-hole stopper.

A 125 ml sep funnel is the best size.

- The stoppers and joints must be tight, since pressure must

develop inside this flask to force the hydrogen chloride gas out through the tubing as it is generated.

Into the 1000 ml three-necked flask place 200 grams of table salt. Then 35% concentrated hydrochloric acid is added until it reaches the level shown in the figure.

Add some concentrated sulfuric acid (96-98%) into the sep funnel and turn the spigot so that 1 ml of concentrated sulfuric acid flows into the flask. The gas produced is then forced by pressure through the glass tubing.

One of the Erlenmeyer flasks containing the product in solvent is placed so that the glass tubing extends into the methamphetamine, almost reaching the bottom of the flask.

Drip in more sulfuric acid as needed to keep the flow of gas going to the product.

- If the flow of gas is not maintained, the product may solidify inside the glass tubing, plugging it up.

Within a minute of bubbling, white crystals will begin to appear in the solution. More and more of them appear as the process continues.

It is now time to filter out the crystals, which is a two-man job.

The flask with the crystals in it is removed from the HCl source and temporarily set aside. The three-necked flask is swirled a little to spread around the sulfuric acid and then the other Erlenmeyer flask is subjected to a bubbling with HCl. While this flask is being bubbled, the crystals already in the other flask are filtered out.

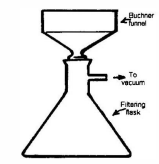

The filtering flask and Buchner funnel are set up as shown:

The drain stem of the Buchner funnel extends all the way through the rubber stopper, because the product dissolves rubber stoppers. A piece of filter paper covers the flat bottom of the Buchner funnel. The vacuum is turned on and the hose attached to the vacuum nipple.

Then the crystals are poured into the Buchner funnel. The solvent and the uncrystallized product pass through the filter paper and the crystals stay in the Buchner funnel as a solid cake. About 15 ml of solvent is poured into the Erlenmeyer flask. The top of the flask is covered with a palm and it is shaken to suspend the crystals left clinging to the sides. This is also poured into the Buchner funnel. Finally, another 15 ml of solvent is poured over the top of the filter cake.

Now the vacuum hose is disconnected and the Buchner funnel, stopper and all, is pulled from the filtering flask. All of the filtered solvent is poured back into the Erlenmeyer flask it came from. It is returned to the HCl source for more bubbling.

The Buchner funnel is put back into the top of the filtering flask.

It still contains the filter cake of product crystals. It will now be dried out a little bit.

The vacuum is turned back on, the vacuum hose is attached to the filtering flask, and the top of the Buchner funnel is covered with the palm or a section of latex rubber glove. The vacuum builds and removes most of the solvent from the filter cake. This takes about 60 seconds.

The filter cake can now be dumped out onto a non-plastic plate by tipping the Buchner funnel upside-down and tapping it gently on the plate.

Filtering continues, with one flask being filtered while the other one is being bubbled with HCl. Solvent is added to the Erlenmeyer flask to keep their volumes at 300 ml.

Eventually, after each flask has been bubbled about seven times, no more crystals will come out.

The filter cakes on the plates will be nearly dry now. With a knife, cut the cakes into eighths, then allow to dry before being chopped up into powder.

The yield is about 100 grams of nearly pure product. It should be white and should not get wet. The crystals are first left on the plate to dry out, and then transferred to glass jars or plastic baggies if not powdered.

The process is completed, and has yielded 100 grams of extremely pure methamphetamine if followed to the letter.

@Fire @TheAlmightyJim @REYNOSO_FUA11 @Ahab (Don’t worry Ahab I left our secret touches out, we’ll still have the best product on the market by far) @MassImpact124 @JimHarbaughWQLVE